Description

In this course, you will learn:

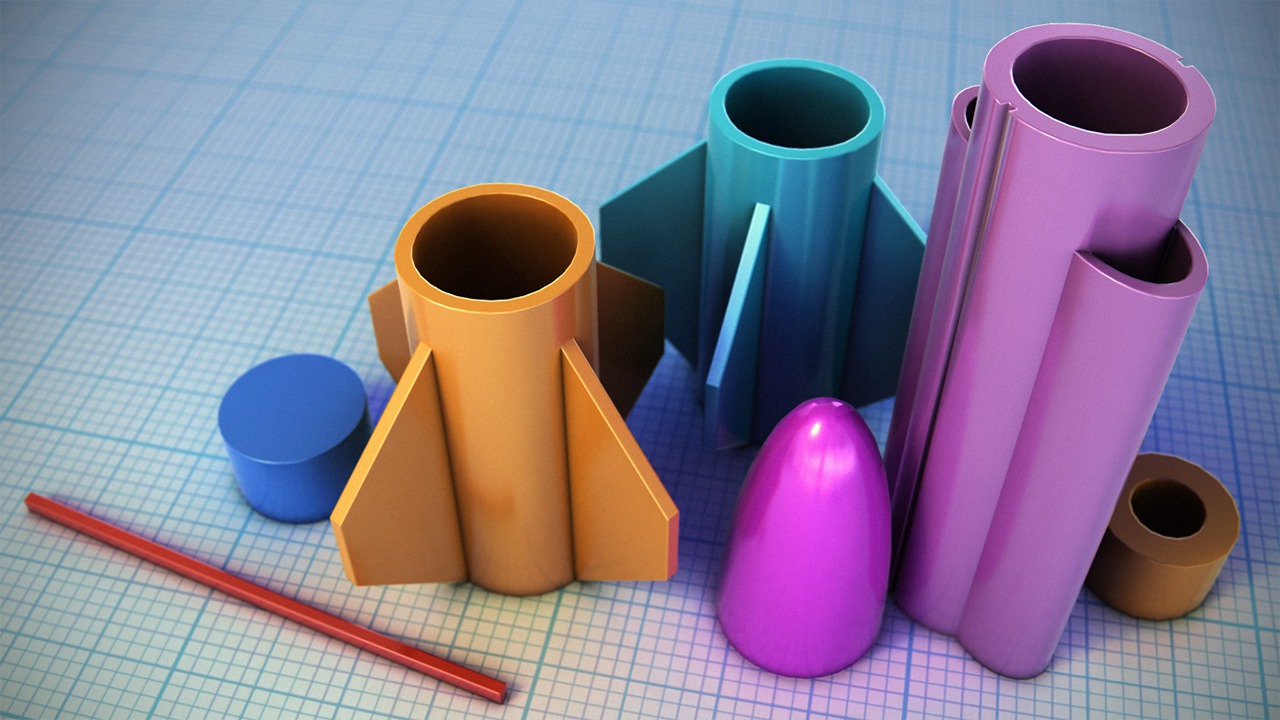

- Learn how to choose the correct material based on your design and printing method, surveying materials that are commonly available for use with desktop 3D printers (filament and resin) along with an intro to industrial materials like nylon and metal powders.

Syllabus:

- Introduction

- Choosing additive manufacturing materials

1. Defining Basic Material Requirements

- Factors in selecting 3D printable materials

- Mechanical properties

- When you do not want to use a 3D printer

- Surface quality and feature size requirements

- Filament, resin, or powder?

2. Filament-Based Printers

- Selecting a filament material

- What materials can your printer use?

- Composites and "metal" filament

- Maximizing production capacity

- Designing parts for lowest turnaround time

3. Resin Printers

- Types of resins

- Maximizing production capacity using resin

- Designing parts for resin printing vs. filament printing

4. SLS, Metal, and Full-Color Printing

- Selective laser sintering (SLS)

- Direct metal laser sintering (DMLS)

- Full-color printing

- 5. Short-Run Manufacturing Case Studies

- Direct printing: Mass customization

- Tooling/molds

- Typical applications